Selecting Bamboo

There is surprisingly little on the web about how to choose bamboo species. I have done a fair amount of research and have figured out a few things. Note before buying your bamboo make sure you look at all the other directions on this page. Each pole will have to serve a specific purpose and as such will need to meet certain specifications (diameters, length between nodes etc).

Local Sourcing & Bamboo in General – A few comments.

Finding it. Sure it can be hard. I found mine by contacting the local chapter of the American Bamboo Society.

It is important that you choose older bamboo poles. Younger poles are not fully developed structurally. Also some poles are born to split, its better to have a pole that his demonstrated its worthiness for your bike. You can generally tell the older poles by looking for weathering, if it looks like a polished pretty thing, its probably very young.

Second, the poles will have the thickest walls near the base of the pole. These thick-walled pieces would be a good choice for your seat tube since it bears a lot of weight. Keep in mind that the rear triangle bears a lot of the brunt too. Choose your pole carefully.

Third, the nodes on the pole are the weakest point. The individual fibers traverse to the other side of the poles. This is apparently the weakest link, so try to avoid using them for structural components.

Fourth, respect the bamboo. Each piece is different. Try to figure out how best to use bends, thick walls, etc to better suit the build characteristics of your bike.

Fifth, (courtesy of Fox.Gao) “One of the reason for bamboo poles split is the time to cut the bamboo poles, the best time to cut the bamboo poles is in Autumn or Winter, not cut the bamboo poles in Spring or Summer—–that is the rain season and the water contents of the poles is too high. Another issue for choosing the bamboo poles is the altitude of bamboo growing, more high altitude means the bamboo grow more slow and more firm.” This advise makes sense. I cut my poles after a very rainy summer in MA.

Finally, you might consider doing a chemical treatment of your bamboo to reduce splitting, and to prevent mold/pest formation. Most of the retail purchased bamboo will have undergone a chemical treatment, so you might do the same. For more detail on this go to the ‘chemical preservation’ section below.

Bamboo Types

Probably the most common bamboo is Phyllostachys or taiwan bamboo:

Taiwan Bamboo (Phyllostachys)

This is the type that I cut from a generous fellows backyard a few months ago. Phyllostachys seems prone to splitting, I lost about 3/4 of my poles during the 3 month drying process, oddly enough the longest poles seemed more prone to splitting. I did learn however that heat treating the poles when green might help avoid this problem. I will get into this later. The poles that did not split seemed adequately stiff and relatively light compared to the phyllostachys negra (black bamboo) that I ended up going with. In the end I choose to purchase some better quality poles.

Black Bamboo Poles (Phyllostachys nigra)

Black bamboo while terribly sexy appears to be prone to splitting also, at least according to bamboo forum folks. The poles that do make it however appear to have thick walls and come in a convenient variety of diameters. In the end this is the only type of bamboo that I found that could meet my diameter requirements. I ordered my poles from bamboofencer.com although you can also get them from bamboohardwoods.com. It’s a bit expensive but the poles are very nice. I ordered three 8 foot, 1 and 1/2″ diameter for the main triangle and three 8 foot 1″-1 1/4″ poles for the rear triangle. Having extra was key. I would recommend buying one additional 1″-1 1/4″ diameter pole (make 4 total) to make sure you have enough to work with (smaller poles have a strong taper and thus don’t give you as much room for error).

Tonkin Bamboo (Arundinaria amabalis)

The bamboo of choice apparently, according to one of my bamboo friends, is tonkin. It is strong light and less prone to splitting…. apparently. This is the type of pole commonly used for bamboo fly rods. Unfortunately I couldn’t get it in the proper diameters, but I just found that bamboohardwoods.com has it.

Heat Treatment

Heat treatment is really frikin important. Apparently it hardens the sugars inside of the canes, kills unwanted guests, and helps remove some moisture. Also, as pointed out by a reader “andreas”, the bamboo poles diameter changes as it gets dried by heat (~3%). This can be problematic if non-heat-treated bikes have prolonged exposure to heat (left in the sun over hot pavement etc). Apparently this shrink can be severe enough to weaken the bond between joints and pole. When it comes to heat treatment, I just do it.

I have read many times that you should use a regular propane torch, starting at the base of the pole work your way to the top. The method to temper the bamboo is to heat it when it is green, with a propane torch, moving the flame up and down the surface of the culm until it changes from shades of green to tan and if desired, to darker shades of brown. I suggest a light browning for the first step. Then you have to dry the stuff, for real. The torch only partially removes the water content. Alternatively if you buy the stuff through a good supplier your poles are likely pretreated and dried. Keep in mind that some of the poles bought from abroad will have been chemically treated, and we all know that chemical regulations in developing countries are lax at best. So be careful and use a proper respirator. Anyways, in this case I would just heat-treat the individual poles that you buy before you use them. Some types of bamboo might react poorly to heat treatment, so keep that in mind if you are having trouble.

Drying

Locally sourced poles however still need to be adequately dried. People on “bamboo forum” have a number of views, but I think stacking them vertically for about 3 months, yes 3 months, does the trick. To avoid getting mold build up make sure that they get adequate air circulation. Also keep them out of direct sun. If you don’t dry them properly (and heat treating them with a blow torch doesn’t count) you are likely to have more splitting problems. Some poles just seem destined to crack, better to find that out before they are part of your bike.

Pole Diameter and Wall Thickness

So far there is only one comprehensive study of bamboo strength and heat treatment. http://www.powerfibers.com/BAMBOO_IN_THE_LABORATORY.pdf. Here are some of the important findings.

Although I haven’t studied physics in a while here is my simplistic take. Your most important poles, requiring the greatest stiffness should have 3mm walls or more. The seat tube and down tube on my bike both have 3mm walls. Your smaller poles (seat stays, chain stays) should be as thick as possible. I believe mine are around 2mm.

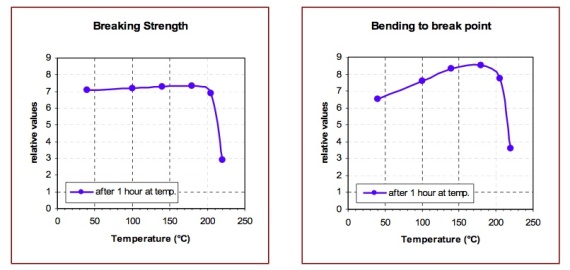

One of the big surprises here was the lack of breaking strength improvement. It does however point to the faults of over heating your poles. Breaking strength declines rapidly after the internal temperature reaches 200 degrees C. The ability to bend the poles increases however. Again we see a rapid failure after 200 degrees C.

Smoking Bamboo

I have also read about smoking your bamboo poles. Apparently you can use scrap bamboo or cracked poles to smoke others. Apparently the tar from the burning bamboo helps to protect the bamboo from mold, pests etc and some site even claimed that it helped avoid cracking… can’t verify that. Some types of bamboo might react poorly to heat treatment, so keep that in mind if you are having trouble.

Although I haven’t tried it this is what I’m thinking. I was planning (didn’t get around to it) to use my father’s old barrel smoker. Soak the bamboo pieces in water and then throw it in.

If you don’t have a smoker you might try to do something like this. You could add a right angle to the air conditioning tube and laying the poles in there.

Chemical Preservation

They use a borax mix to help create poles that are inhospitable to bug, molds etc. This process should also reduce splitting. Many of the higher quality poles you can buy online go through a similar process.

For more info on professional grade bamboo preservation go to: http://www.bambooman.com.au/bambootreatment/ebf.php

Another good option is this Bamboo_Treatment_Manual from The Environmental Bamboo Foundation

Recommended Suppliers

No I’m not getting paid to say this. I just think this is the best bet (until I hear otherwise).

Zack Jiang at Stalk Bikes has opened an ebay store to sell bamboo bike building materials. So, he knows what he’s doing because hell he does it for a living. So support the creative guys of the world and buy your building materials here.

“Bamboo Habitat now offers bamboo selected specifically for building bikes. This bamboo has been selected by going through the bamboo groves and choosing the oldest bamboos that have the proper diameters. By selecting the oldest bamboo, we are getting the maximum fiber content, which assures that the bamboo is very strong. The bamboo is then power washed and then kiln dried. The types of bamboo we have are Black Bamboo, Madake Bamboo and Blue Henon Bamboo. Of the three, the Henon Bamboo is the strongest, but the Black Bamboo and Madake are also exceptionally strong.”

“Bamboo Habitat now offers bamboo selected specifically for building bikes. This bamboo has been selected by going through the bamboo groves and choosing the oldest bamboos that have the proper diameters. By selecting the oldest bamboo, we are getting the maximum fiber content, which assures that the bamboo is very strong. The bamboo is then power washed and then kiln dried. The types of bamboo we have are Black Bamboo, Madake Bamboo and Blue Henon Bamboo. Of the three, the Henon Bamboo is the strongest, but the Black Bamboo and Madake are also exceptionally strong.”

Links

www.bamboocraft.net/ Tons of topics, more detail than you need

www.bamboohardwoods.com Supplier of bamboo poles: Tonkin, Black, Moso

www.bamboofencer.com/ Supplier of bamboo poles: Tonkin, Black, Phyllostachys

http://www.americanbamboo.org/ All kinds of bamboo info

http://www.bamboocraft.net/forums/archive/index.php/f-111.html More info on bamboo treatments

International Network of Bamboo and Rattan

Building with Bamboo… the book

Although completely unrelated. Check out my family’s farm. The site is just up… here it is.

Posted by foxgao on March 31, 2010 at 4:25 pm

you are making a wonderful things!

One of the reason for bamboo poles split is the time to cut the bamboo poles, the best time to cut the bamboo poles is in Autumn or Winter, not cut the bamboo poles in Spring or Summer—–that is the rain season and the water contents of the poles is too high.

Another issue for choosing the bamboo poles is the altitude of bamboo growing, more high altitude means the bamboo grow more slow and more firm.

I can’t open most of the picture in your website—I don’t know why, have you ever test your bicycle? Does that really safe for riding?

Can you give me an email? As I have so many question want to ask about the bamboo bicycle.

Thanks & Best Regards,

Fox.Gao

Posted by mmann1123 on April 1, 2010 at 12:30 am

Great thanks for the bamboo input. I will update my bamboo info page.

Posted by Margaret M on April 28, 2016 at 5:29 pm

Addendum to pointer re harvesting during dry season: west of the Rockies of North America, the wet and dry seasons are reversed from central/eastern North America or east Asia. Generally, late spring/summer/early fall here is the dry season, and late autumn/winter/early spring is the wet season. Of course, this varies in detail greatly by location, and there can be quite different microclimates within a relatively small geographic area, for instance in the San Francisco Bay Area. Some coastal areas may at various times have low rainfall but be prone to fog. I wonder what the effect of fog is on timing of cutting bamboo, vs. the effect of rain.

Posted by Margaret M on April 28, 2016 at 5:56 pm

Here is a detailed discussion from one of your links re: when to cut bamboo according to the season, time of day, year in the lifecycle of the plant, etc: http://www.bamboocraft.net/forums/archive/index.php/t-3582.html

Posted by marcin on June 1, 2010 at 4:52 pm

Great Webblog 🙂

I have a question about the heat treatment. is this true if I don’t punch out the nodes inside the bamboo prior to the start of heating the pieces – bamboo WILL EXPLODE? Because between nodes is a pocket of air .

Another thing is how far is it important to do that with an already dry (black) bamboo?

Posted by mmann1123 on June 1, 2010 at 11:22 pm

I did not remove the nodes from any of my poles. Although I can’t make any promises here I would assume that removing nodes would make your bamboo structurally deficient. The node is where all the individual fibers literally cross over to the opposite side of the pole, and as such is one of the weakest points to begin with. Removing the node would only further weaken the structure.

In terms of heat treating. I did not drill out nodes nor did I drill venting holes.

If you cut your own fresh bamboo: The drying process however facilitated by heat, but should be done primarily with patience. After cutting you poles to rough size, use a propane torch to lightly brown the poles. I think this will harden some of the sugars and help avoid some cracking during the drying process. Then hang your cut bamboo poles somewhere upside down, have constant air movement (reduces fungus), and little exposure to direct light. Then wait… about 2-3 months. Then go back at it with your torch, if your poles haven’t cracked by then you should be in the clear (expect at least 30-50% to crack, although it depends on when you cut your poles and the bamboo type). Also one reader recommended that you cut your bamboo down during a dry period like fall, when the water content of the poles is lower. This also might help.

If you buy predried/treated poles: This makes the process a lot easier. First I would sit on them a bit (ie wait), see if the shipping process or the change in climate cracks any poles. Go over them carefully to make sure there are no micro cracks, especially around the nodes. Then cut to length and heat treat.

Posted by marcin on June 4, 2010 at 2:50 pm

Thank you for all the infos 🙂

I want to build my bike in Austria- let see what happens 🙂

I also found a guy who is importing bamboo from all over the world to Austria. I already spoke with him. He has really a huge sort of bamboo, so I can go there and choose what I want:)

I have one more question to you – how thick or strong should be the walls of the bamboo?

Posted by mmann1123 on June 9, 2010 at 10:16 pm

Wow that is hard to say, it really depends on which tubes you need them for. Your seat tube should be beefier than the rest maybe 3mm or thicker walls, I get my caliper out and test some of my poles sometime soon to check for you. I would think 1.5-2.5 mm walls should do it for the rest.

It seems like strength is also a species specific quality also. Some bamboos are used traditionally for structural building materials while others are avoided. If you have questions about specific bamboo types I might be able to ask my bamboo pro friend here or you might float a question at http://www.bamboocraft.net/

Posted by How to build a bamboo bike » Cyclelicious on June 7, 2010 at 2:31 pm

[…] his blog, Mike writes about bamboo selection, the metal parts you need and how to get them, the all important frame jig, mitering […]

Posted by How to build a bamboo bike « Bike Monkey Magazine on June 7, 2010 at 2:46 pm

[…] his blog, Mike writes about bamboo selection, the metal parts you need and how to get them, the all important frame jig, mitering joints, […]

Posted by andreas on July 9, 2010 at 4:35 am

hey, good morning,

recently we built up our first prototype bamboo bike. But unfortunately we had some problems:

We cant manage the temperature treating process. In fact we realiced the brown colour of the bamboo, but either the tubes crack while heating or while cooling afterwoods – where is the mistake? We heat either by gas flame or by cole barbeque because we dont have that big oven. heat treatment time of one internode section is around 10min. all of the nodes are drilled to avoid pressure in the internode sections.

why is the heat treatment that important? Is it for getting better physical conditions of the bamboo in stregth and stiffness, is it for conservating it or does also the conditions for the glueing process improve? – could one also use non heat teated bamboo?

Posted by mmann1123 on July 10, 2010 at 8:30 am

These are all good questions. Bamboo is a fickle material to use. There are a few general categories of issues:

1) Bamboo species: Many species are inappropriate for building as they are prone the cracking. I would recommend tonkin.

2) Harvest issues: Bamboo shoots should be mature when they are cut, 3-4 year old. Many immature poles are sold, make sure you know your source. They also should be cut during a dry season to avoid having waterlogged poles. Either of these could be issues in your case. Look at my section on bamboo selection for more detail.

3) Chemical treatments: There are a number of chemical treatments that can be used to reduce splitting. Look at my section on bamboo selection for more detail. This can be tried before heat treatment. Just make sure you wear appropriate protection for chemical vapors when you heat your poles later.

More specific comments:

1) I would avoid drilling holes in the poles. This will create a structural weakness that might come back to haunt you.

2) I am assuming that you are using a torch to brown the wood. Note that this is not intended to dry the wood. It should take about 1-2 minutes to heat each node. Think of this process as solidifying the starches in the poles, not drying them. After doing the 1-2 minute torching, put the bamboo poles (stack vertically) in a well circulated, dry place for about 2-3 months if the poles were just cut. I know it sucks but that is just how it works. Speeding up the process is unlikely to produce the desired result.

3) One issue with cracking is the sudden change in temperature. Try putting a towel over the sections you just heated up, to help them cool more slowly.

4) The heating process is important because it acts to stiffen the bamboo poles (it is much harder to cut through a heat-treated pole than a non-heat-treated pole) and renders there sugary sweet insides into an inhospitable climate for bugs and grubs. Note that a chemical treatment also reduces the impact of bugs/mold/etc. So if you are really having trouble, try just using the chemical treatment. I would assume however that the poles would not be as rigid.

5) It is quite possible that none of these tricks will work. If so, find some better poles. Some are just born to crack on you.

Posted by Guilherme Korte on September 23, 2016 at 6:26 am

Bamboo poles comes from everywhere. Dry plateau, rainy season, wet mountain, flat and sandy land, and more different origin. Same fiber, distinct textures. Like in South Korea, they cut during winter to avoid starch in pole, and they heat with fire also to come internal oil to the surface, in Phyllostaquys genera. In Brazil we have many different treatment for poles. I never saw one same as other. Cooking is more efficient. Easy and you can add cooking oil to make it more waterproof and soft, add some veterinary

medicine with chlorpyrifos and cypermethrin – against tick and horn fly, add a color to make your stamp. The cooking must have a thermometer to keep more than 75º C celsius for 2 hours. After that put in shadow until became 12% dry – use a simple moisture meter. A steel or iron single tank, put fire below and that’s it. Be happy and safe with your product.

Posted by Dave on July 27, 2010 at 3:18 pm

Hey, great blog you’ve got here. It’s been a lot of help while I have been building my bike.

Anyway, I found a great article on heat treating bamboo here: http://www.powerfibers.com/BAMBOO_IN_THE_LABORATORY.pdf

In this article it says that a torch is not ideal in removing all the water. They recommend putting it in the oven at 180C for 10-18 minutes, and then using the torch for cosmetic reasons only. According to them, this is the optimal method for losing the most water, and having a high strength.

Posted by Jeremy on August 12, 2010 at 3:11 pm

I thought you also might want to consider D. strictus as a source for making your frames. Yucatan Bamboo can provide you with high quality cane. http://www.yucatanbamboo.com

Posted by Paul Wujek on September 7, 2010 at 6:48 pm

Yucatan Bamboo may no longer be a viable source, here is a reply to email I sent to them:

Thank you for your interest in Yucatan Bamboo.

We no longer have inventory in the U.S. Our bamboo plantation and factory are located in Yucatan, Mexico and our administrative office is in Houston, TX. All of our orders are custom made.

We just had a shipment clear customs last week and so we currently do not have another shipment scheduled. Therefore, we could not fulfill such a small order as yours at this time.

The poles would be $8 each at the length you request. The diameter requirements would be no problem. Would you like me to keep your information on file and when we receive larger orders I could call you?

I am sorry we could not help you at this time. We look forward to hearing from you as to what you would like for us to do.

Regards,

Joyce French

Sales & Marketing Manager

Yucatan Bamboo, Inc.

713-278-7344 (office)

713-586-9616 (cell)

http://www.yucatanbamboo.com

Posted by Jason on September 12, 2010 at 3:00 pm

Hey, with regards to head treating, i remember reading that boo bicycles dont bother with heat treating thier bamboo as its already stiff enough (they use iron bamboo)

Cant recall where i read it, but its in an interview with nick frey on the interweb somewheres.

If the treating could be skipped then it would sure save alot of hassle with cracked tubes etc …. my view is that by far the majority of the flex on bamboo bikes is in the joints, not the poles. Has anyone built without heat treating ?

one more thing, you mentioned that wrapping the poles in a towel to slow the cooling helps reduce cracking … I do this myself and have found it to be pretty much essential! it really helps ALOT.

Posted by mmann1123 on September 12, 2010 at 9:58 pm

I think that whether or not you skip drying depends on the type of bamboo and the quality of the poles. I think thinner walled poles might need the additional rigidity from hardening to avoid cracking (or at least to identify poles that would crack anyways). Additionally heat treating will reduce bug problems since sugars are hardened. Although it might be unnecessary if the poles you are using have been chemically treated (as the majority of quality commericial poles probably are).

Additionally, although I suggest using the towel trick for heating poles, I have to admit I have never had a pole split on me while heat treating it (even without using a cloth). But it seems like a very common problem.

Posted by andreas on September 13, 2010 at 2:45 am

Good morning,

I once skipped heat treating the bamboo and I would not advice you to do so as well. As we have seen the bamboo shrinks in direction of diameter around 5% till 10% (almost no shrinking in direction of length), from the air-dried state to the heat-dried state. So what happend when we skipped the heat treating was, that the bamboo went on driing when already assembled in the bike frame because we faced the frame with the very hot july sun. Once the bike was tested in traffic the whole frame broke, because the poles shrinked and lost their contacts to the joints. (nobody was injured) But one could physically see the slit between the poles and the joints. By the way, the joints cracked, not the poles.

Additionally one has to say, that we use fully dried bamboo, which we heat treat before assembling. As I read some do it the other way round. Buying green poles, heat treat them and let them air-dry afterwoods for some months before assembling. Dont know if that makes any differences.

Best regards

Posted by Miro on September 21, 2010 at 1:56 pm

Hey,

First I have to say, your bike looks just awesom and your Blog is GREAT! Thanks a lot!

I’m a student from zurich and I’ll build a bamboo for a school project. I write about it in my Blog:

bambusrad.blogspot.com It’s in German, but maybe you can post it in your blog, I will do the same with yours if you dont mind.

In three weeks I want to start maching the frame together and I have a question.

I want use Tonkin Bamboo but I will buy it allready dried. Do you have any experience or advises in heattreating allready dried Bamboo?

Maybe there later will be some more questions…:)

Greez

Miro

PS: Sorry for the bad english 😉

Posted by mmann1123 on September 21, 2010 at 6:02 pm

Awesome I will take a look at your blog in a bit. As for heat treating dried bamboo. I used pre-dried bamboo in the end. I also did a minor heat treatment. I would recommend you do the same.

Posted by Paulo Aveiro on March 13, 2011 at 9:26 pm

Hello noble friends, I am Brazilian and artisan bambuseiro, surviving with my work is fantastic plan, I have great experience overall in the manufacture of furniture in bamboo am now seeking knowledge to manufacture bamboo frames for bikes, well I have provide to contribute to this blog . on the treatment of bamboo

01 – use torch to realiamento bamboo observation of cells always start with the torch flame in estrimidade the party was sawn into the soil to the tip with the flame will never go back to the back so when the cell is disoriented with the flame front to so doing small areas at a time as two of the bamboo culm.

01 – note when it is burned with the flame torch bamboo starts to get wet for a substance called honeydew and foamy sugar and starch that the fire is spewing out.

03 – the secret of this substance is cleaning the diesel oil with a rag pasa in this area after removing honey and a dry rag to finish.

04 – the bamboo should be bump in the waning moon and posivil in winter because it allows the sap in the rhizomes and has less possibility of drills etc … some words were exchanged excuse I use the google translator and translation is not always the same but here’s my purpose to help noble friends.

My blog pauloaveiro7@blogspot.com

E-mail bambusull@yahoo.com.br

Posted by Jason Richards on May 4, 2011 at 5:55 pm

Can you use Bamboo poles that are bought from somewhere like Home Depot or Lowes? I don’t think they are heat treated…maybe they are, but they are dried. Has anyone had experience using these types of bamboo? The reason i am asking is that I live in Utah where it seems that finding green bamboo is hard to come by.

Posted by mmann1123 on May 4, 2011 at 7:48 pm

I can’t say I have ever seen the bamboo at lowes. However I am under the impression that they are likely young taiwan poles (since they are cheap and plentiful). They might work, however if they are cut very young they are likely to have very thin walls and underdeveloped nodes. Anyone else have some thoughts?

Posted by Jason Richards on May 5, 2011 at 12:44 am

Does anyone have recommendations on where to buy Bamboo online? I have seen people sell them on ebay but I don’t know if they are quality. Has anyone had experience with buying them on ebay or online and had them shipped?

Posted by mmann1123 on May 5, 2011 at 8:17 am

Jason, there are a number of online bamboo sellers. Bamboohardwoods is one, bamboofencer is another. I used bamboo fencer for my bike. The poles were high quality and reasonably priced. Links to the sites are provided in the links section above.

Posted by Jason Richards on May 5, 2011 at 9:40 am

I will look there. Thank you! Do the poles come still green?

Posted by mmann1123 on May 5, 2011 at 10:28 am

Nope. They were dried and chemically treated to prevent cracking and molding.

Posted by Jason Richards on May 5, 2011 at 10:54 am

Sorry to be such a noob about the subject, but does that make a difference in the strength of the bamboo if it is not heat treated?

Posted by mmann1123 on May 5, 2011 at 5:25 pm

The graphs above suggest that strength doesn’t improve much, but pliability does. However, heat treatment has other important features. Most importantly it decrease the likelihood that you will have pests, or molds. So you poles will last longer etc.

Posted by Jason Richards on May 9, 2011 at 2:31 pm

Has anyone seen how the bamboobikestudio.com guys are using foam for the lugs and joints? Is there a benefit to doing it this way?

Posted by zakolantern on May 11, 2011 at 5:53 pm

Jason, Bamboo Bike Studio uses foam to form the structure of their joints instead of mitering the bamboo itself, for simplicity of construction, essentially. — Zack Reiss-Davis

Posted by Whitney on June 4, 2012 at 5:48 pm

It is not just for simplicity of construction. The foam serves to locate the composite (carbon fiber) in a position where is gives the most strength. In this case, it is the strongest when it is away from the actual intersection of the bamboo poles. It is just like having a gusset plate in a welded/bolted joint. Just think of the contours efficiently transferring the load from one pole to the other. Besides, it looks good!

Posted by zakolantern on May 12, 2011 at 1:39 am

What are the bamboo diameters you use on the various parts of the frame? Thanks. — Zack Reiss-Davis

Posted by zakolantern on May 12, 2011 at 1:46 am

Sorry for the double-post: As one way to think about it, I measured the photo Calfee posted, and am considering using their dimensions (pretending their photo was a scale model of a bike, and using the 700 cc wheels for my scale). For anyone who is curious:

2 inch diameter tube BT

1 5/8 inch in diameter tube TT

1 3/8 inch ST

1 inch bottom rear dropout tube

3/4 inch top rear dropout tube

Source:

Posted by zakolantern on May 12, 2011 at 1:46 am

Sorry for the double-post: As one way to think about it, I measured the photo Calfee posted, and am considering using their dimensions (pretending their photo was a scale model of a bike, and using the 700 cc wheels for my scale). For anyone who is curious:

2 inch diameter tube BT

1 5/8 inch in diameter tube TT

1 3/8 inch ST

1 inch bottom rear dropout tube

3/4 inch top rear dropout tube

Source:

— Zachary Reiss-Davis

Posted by Jason Richards on May 13, 2011 at 9:19 am

I came accross these bamboo poles at a local hardware store. They are made by a company called Waddell Manufacturing. Supposidly they are kiln dried. Here is a link that has some info http://halehardware.doitbest.com/Wood+edging+and+molding-Waddell+Mfg+Company-model-6264UBG-4-doitbest-sku-165074.dib

Anyone have any thoughts as to if these might be a viable solution for a bamboo bike?

Posted by mar on June 19, 2011 at 4:37 pm

Hello!!

What I would like to know is: do you put some transparent lack on the surface of the bike? How do you protect the bamboo bike against all day influence, and weather- rain , snow etc.?

Do you know how the bamboo react on this and how strong does it influence on the life time of the frame?

Reagrds

Mar 🙂

Posted by Marie Mullen on August 8, 2011 at 9:26 am

What sort of health issues can arise due to chemical treatment? (This is for a home) My bamboo is coming from Vietnam and I know that there are massive differences in how things are regulated oversees. Which method is best and what should I avoid? Thank you

Posted by mmann1123 on August 9, 2011 at 2:16 am

I have to defer to other readers on this one.

I think that in general you should proceed with some caution. You never know what they use. I think the primary exposure will be dust. So I would recommend getting a proper respirator which is not expensive (15-20 bucks). Also, any one who is pregnant should probably avoid the process at the moment ( I noted that high level exposures can cause birth defects from Tim-bor). Hope this helps. Others, please contribute if you can.

Here is a link to Tim-bor which I think is commonly used, (might be the same as boric acid, not good at chemistry)

Click to access TimborMSDS.pdf

Posted by Blake on September 1, 2011 at 5:57 pm

Do i buy a regular bamboo pole or hallow bamboo poles?

Posted by mmann1123 on September 5, 2011 at 5:53 pm

I would use regular poles, not drilled out ones…

Posted by Miro on September 7, 2011 at 6:41 am

I would buy regular poles and drill them out. My tubes splittered because the temperature changed to much. I Think if i drilled them this wouldn’t have happened because the air would have enough space to spread.

Posted by Martika on April 17, 2012 at 9:31 pm

Hello,

My name is Martika Jenkins. I represent a team of undergraduate students from engineering and business backgrounds in a course called Affordable Design and Entrepreneurship. We are working with an Alabama community development non-profit, HERO, who has started a new venture manufacturing bamboo bikes. This is the first time that I have heard about them and am looking to talk to experienced riders/builders to learn more about them.

From your blog, I can see that you have a lot of experience working with bamboo bikes. I am looking to talk to you to better understand bamboo’s strength, durability, and potential.

Posted by Juan Estrada on May 29, 2012 at 2:39 pm

Hello,

what are your thoughts on naturally dry bamboo? I live in a tropical country and bamboo grows naturally everywhere around here, so I know I can find poles which have dried out naturally for a variety of reasons. There will of course be weathering issues from it being exposed to sun and rain, but some of it might be properly seasoned. Do you think it would need heat treatment as well?

Posted by mmann1123 on May 29, 2012 at 3:29 pm

Wow… ok I think that it is probably best to cut and dry them yourself. I would be worried about pest and disease in planted dry poles. If you cut, dry, and heat treat your own poles you can best control the process. You might consider using a chemical treatment too, to prolong the life of the poles.

Posted by F P on August 7, 2012 at 10:06 pm

Hi. Great page! I’m confused. I just started torching some bamboo pieces with propane. Should I also chemicaly treat once dried, now or not ever? I’m not sure what type of bamboo I have- I cut it down myself, but seems so far darker than I’d like. Any suggestions? And some exploded on me while torching. After first time I now always wear ear plugs and sun glasses. I’m not sure what I was doing to make them explode. It just cracks it with a pretty loud pop and steam and resin shoots out.

Posted by mmann1123 on August 13, 2012 at 9:01 pm

I wouldn’t worry about the chem treatment at this point. As for the explosions etc, it most likely that the bamboo isn’t dry enough yet. You really need to make sure that the bamboo you use isn’t going to crack on you down the road. A long drying process should help avoid using any duds.

Posted by Persia on October 14, 2012 at 7:39 am

What, no pictures?

Posted by chepilo on November 29, 2012 at 10:16 pm

Excellent links and review compared to the many I have read!

I cannot list all the details, but I am interested in building a bamboo trike. I have learned a lot from various sources all on the web. The toasting that is performed on the outside heats the outside before it heats the inside. As the heat moves into the culm the outer shell begins to cool and tighten as the inner expands under the changing temperature. This will cause splitting wherever the culm is weakest and depending on how much heat was transferred from the outside to the inside. Using a cold wet rag will help dissipate the heat soon enough that the inside does not expand and blow open a hole/crack. I plan on doing some testing on my own to discover more techniques for enhancing the bamboo, but I need some material. I am going to start with scraps from local resources and from whoever can send me their junk culms. Mostly, I want to harden the ends of the poles and develop a way to stiffen without cracking.

Posted by frano on March 30, 2013 at 1:53 pm

how much do bamboo poles cost? i found alot of information about bamboo but i cant find price

Posted by Justin from LIthuania on June 13, 2013 at 9:30 am

Im so in to this, i want to do the frame so much, but the hardest thing is to get the bamboo. There is no one who can ship the bamboo to Lithuania O_O

Posted by rajan on July 11, 2013 at 12:42 am

How to protect the bamboo furniture from insects is very important, I request the people who has practical knowledge on it to share through is ..

Posted by Cloclo on January 14, 2014 at 10:08 am

Thank you for the useful info. I have a bamboo bike whose seat tube measures 40mm in diameter in order to accommodate a seat post if 27.2mm. However, I can’t find a clamp adaptor for front derailleur that measures 40mm. The biggest size is 34.9mm. Do you have any suggestion on how to get around this problem? Thank you.

Posted by mmann1123 on January 15, 2014 at 10:44 pm

I have never dealt with front derailleur. You might bring it by a bike shop and see if you can use large clamp with an extra long bolt.

Posted by google.com on July 2, 2014 at 4:46 am

Nice blog here! Also your website loads up fast!

What host are you using? Can I get your affiliate link to your host?

I wish my website loaded up as fast as yours lol

Posted by Drew Crow on November 3, 2014 at 10:19 am

HEAT TREATING IN AN OVEN. I made a clay oven with an old lemon juice barrel that just fit a metre length poles. It´s just a firepit at the bottom front of the barrel and a sealed tunnel for the heat and draw underneath, up and over the top of the barrel. Id coated the poles with entropy eco resin twice before heat treating, because the epoxy is stronger after a postcure. 100-130 degrees for 10-15 minutes worked fine. The steam forced the epoxy off the poles slightly but I just smoothed it back on while it was still soft under the heat. Nice finish. You can see the chlorophyll blacken in dots at the ends in the bamboo width, which was a good scope for knowing when the poles had had enough. The lighter types of bamboo darken very slightly, but i wouldn´t wait for it, because they turn to charcoal very quickly. One pole I´ve tried that was already mitred split, so I´d save that for after this prep. Also, KNOCK OUT YOUR NODES first, otherwise the pole explodes under the pressure. Carbon fibre in epoxy seems to handle that heat aswell, if anybody fancied making a bike size oven (airtight firepit, move the fire out and bike in) that would be sweet.

Posted by David on May 13, 2015 at 8:56 am

I am wondering if I purchase poles that have already been kiln dried, must I also heat treat them with a torch?

Posted by marcos on December 12, 2016 at 2:09 pm

im building my bamboo bike here in brazil, i call it by “brisa”, hahha, i am searching some infos about the type or tickness of the bamboo, the material to use with resin, if tissue, if fiber glass, if natural fibers, but i believ ill show soon it ready.